Introduction

In today’s world of high-performance manufacturing—driven by aerospace innovation, automotive electrification, and advanced industrial components—precision is everything. Vertical Machining Centers (VMCs) play a central role in achieving this. Through precise cutting, milling, drilling, and contouring, VMC machining ensures that even the most complex components meet exacting tolerances and performance standards.

What Is Precision VMC Machining?

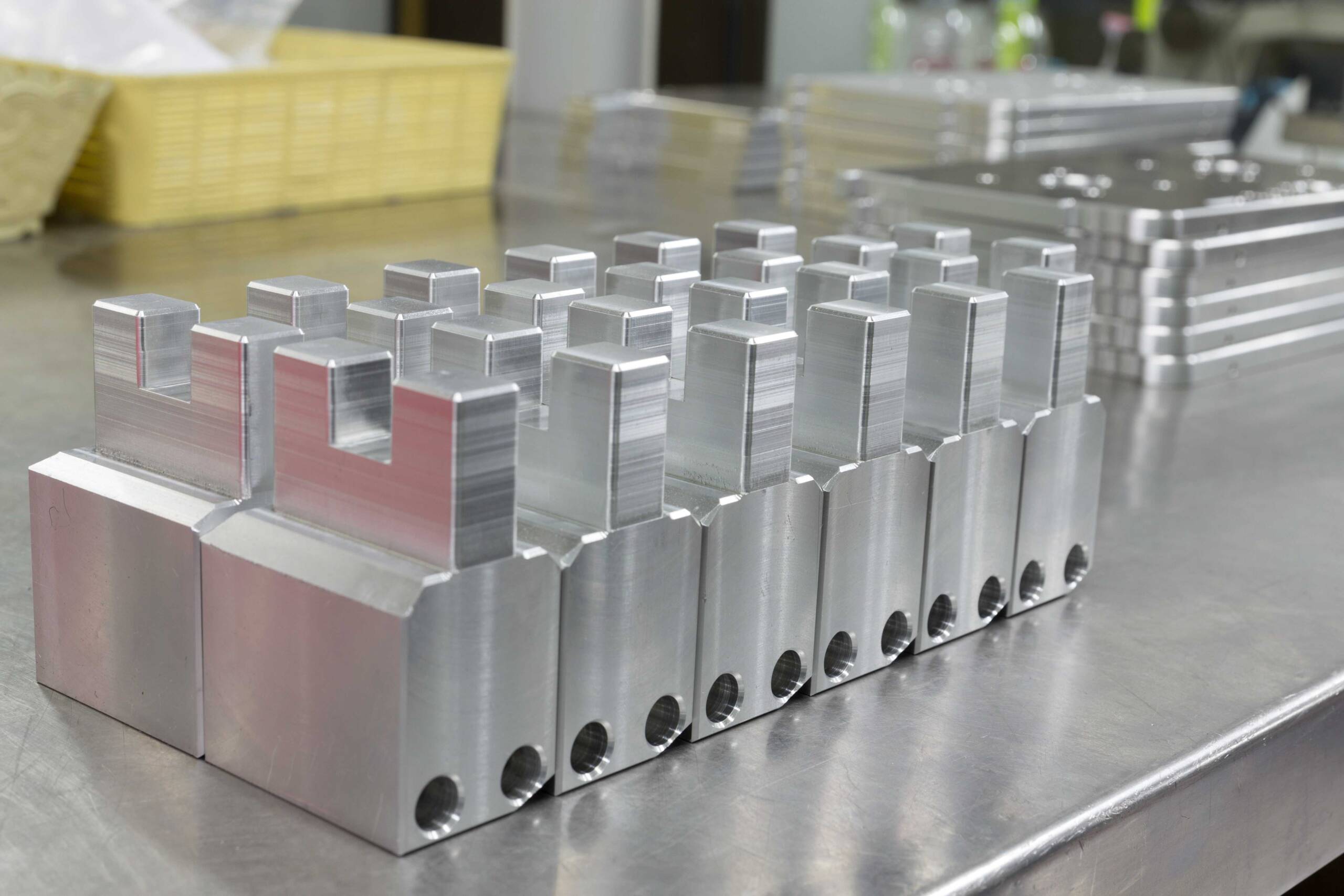

VMC machining is the process of using computer-controlled vertical milling equipment to manufacture high-accuracy parts. Unlike conventional machining, VMCs integrate CNC technology, allowing for complex geometries, repeatability, and consistency across large production runs.

Key Advantage: Tight Tolerances and Repeatability

VMCs excel at maintaining dimensional accuracy with tolerances as close as ±0.005 mm. This is crucial for industries where precision directly translates to performance and safety.

Benefits include:

- Superior accuracy for intricate designs and components

- Repeatability across mass production with minimal deviation

- Capability to machine a wide range of materials (steel, aluminum, copper, composites)

- Reduced cycle times through high-speed machining and tool path optimization

Engineering Precision and Customization

VMC machining isn’t just about material removal—it’s about engineering efficiency. With CAD/CAM integration, simulation, and real-time tool monitoring, manufacturers can achieve optimal balance between surface finish, dimensional stability, and production speed. Custom fixturing and multi-axis machining further expand design possibilities.

Applications Across Industries

Precision VMC machining is indispensable in:

- Aerospace turbine blades and structural components

- Automotive engine parts, EV motor housings, and precision gears

- Medical implants and surgical instruments

- Industrial molds, dies, and high-tolerance machine parts

Why VMC Over Conventional Machining?

Compared to manual or traditional machining, VMC machining delivers

- Consistency in high-volume production

- Complex part geometry with fewer setups

- Faster turnaround with automated tool changes

- Higher efficiency with minimal human error

Engineering Support and Services

Leading VMC machining providers offer more than production—they provide solutions. Services include design optimization, prototyping, surface finishing, quality inspection with CMM, and compliance with international standards.

Conclusion

In a landscape where accuracy, efficiency, and scalability define competitiveness, precision VMC machining stands as a cornerstone of advanced manufacturing. For industries seeking uncompromising quality and repeatable performance, VMC machining delivers excellence—every cut, every time.