Introduction

Behind every mass-produced component lies a tool or die that defines its shape, accuracy, and repeatability. Tool & die manufacturing is the unsung hero of industrial production, ensuring consistency from the first to the millionth unit.

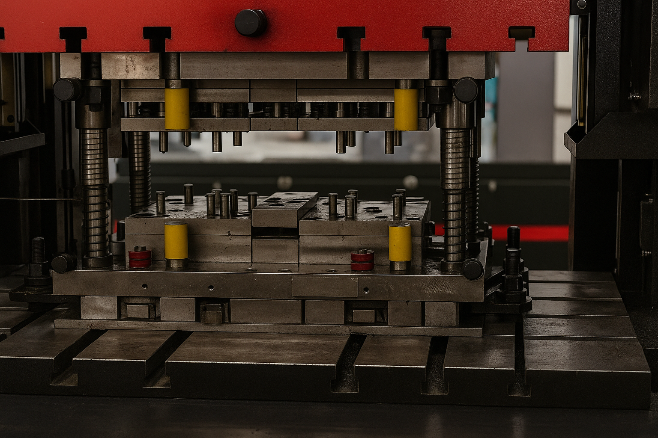

Tool & Fixture Design – Blueprint of Precision

The process begins with 2D/3D CAD modeling, progressive and compound die layouts, and customized jigs and fixtures. Integrated workflows minimize setup time, reduce rework, and ensure compatibility across production environments.

High-Performance Tool Manufacturing

Using wear-resistant steels like HCHCR, D2, and EN31, tools are built to withstand high-stress manufacturing environments. Capabilities such as Wire EDM, surface grinding, and polishing deliver unmatched dimensional accuracy and extended tool life.

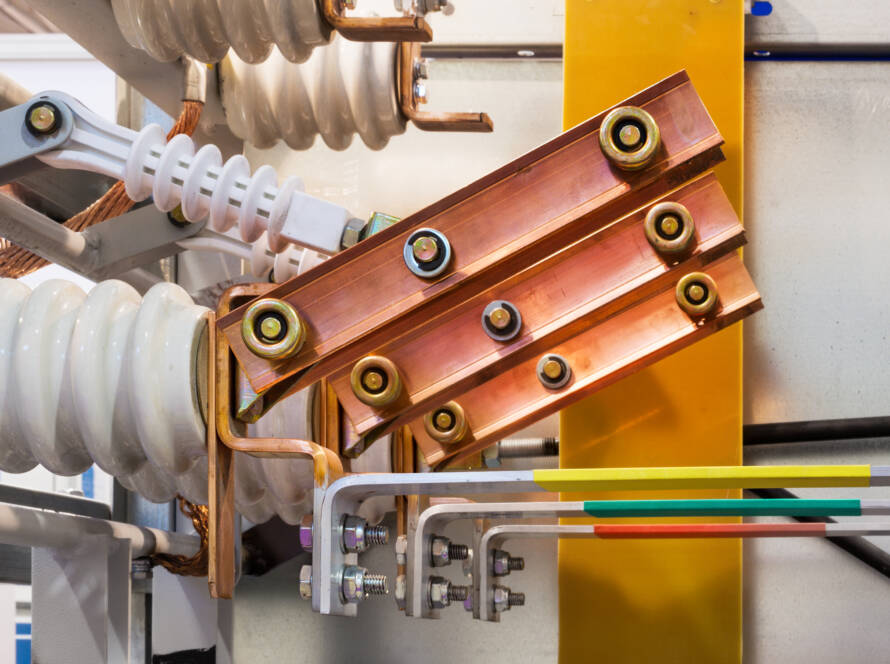

Jigs & Fixtures – Accuracy, Every Time

From welding to inspection, jigs and fixtures lock components in place for flawless repeatability. Modular designs allow scalability and quick changeovers, improving production agility.

Wire Cut & EDM Services – Precision Without Contact

For intricate shapes and tight tolerances (±0.005 mm), wire EDM offers burr-free edges and complex profiling without compromising material integrity—ideal for die inserts and mold cavities.

Benefits to Manufacturers

- Improved product quality through precise forming

- Lower long-term costs with durable tooling

- Faster ramp-up times for new production lines

- Scalability to meet fluctuating demands

Conclusion

Tool & die manufacturing is not just about making tools—it’s about enabling industries to produce with consistency, efficiency, and confidence. As product designs grow more complex and production cycles tighten, the role of precision-engineered tooling becomes more critical than ever.